Barcoding, Barcode Scanners & Generators

Post on Wednesday, November 29th, 2017 in Accounting

Barcodes have become an integral part of our day-to-day lives, even if you don’t consciously think about them.

Scanning barcodes allows the opportunity to get information about products quickly and easily. It makes any type of business more streamlined, and takes the headaches out of inventory management.

But have you ever thought about how barcodes and barcode scanners actually work? Even if you’ve used barcodes for inventory management, you might not know where they came from, why they are the way they are, or how they developed over time.

In this article, we will get to the bottom of these questions, from the history of barcoding to uses, types, and industries that benefit most from barcode scanning.

History of Barcoding

It all started back in 1948, when Bernard Silver and Joe Woodland created hardware that could automatically scan barcodes at grocery checkouts.

The first barcode actually looked very much different from modern barcodes. It consisted not of stripes, but of concentric circles—the so-called bullseye barcode. The first barcoding scanner used a conventional lamp to illuminate product labels and a photomultiplier to read the light that was reflected off them.

The idea was patented in 1952. Later, the patent was purchased by RCA. The electronics company was using it for a range of commercial applications until it expired in 1969.

In 1970, grocery stores were trying to create their own barcoding systems, but all of those systems were different from others and this could lead to a whole host of problems. Therefore, in 1971 Alan Haberman, executive vice president of First National Stores in Boston, suggested to establish the Uniform Code Council (UCC). This later became known as GS1 US, the organization that is now responsible for the scanning barcode standards used worldwide.

In the same year, George Laurer at IBM started to develop the Universal Product Code (UPC), the modern barcode that consisted of black-and-white stripes. In 1973, this barcode was set as a standard barcode for grocery stores.

The first barcoding scanner that supported the UPC was used in 1974 at Marsh’s Supermarket, Troy, Ohio. The first barcode-labeled product picked up by this scanner was Wrigley’s chewing gum.

What Are Barcodes Used For?

Barcode scanner apps let you keep track of your products, prices, and inventory levels. Scanning barcodes gives you more flexibility with prices. You can change the prices any time and adjust them to the market trends.

As a result, there is no need to put new price tags on all of your items. Besides, barcode scanner software gives you more oversight and confidence – for example, you can easily track down the missing items.

How Do You Generate Barcodes?

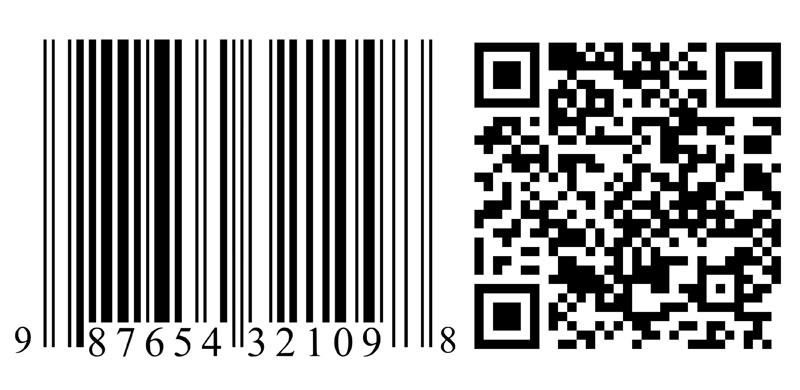

A barcode is actually a unique item number where each digit from 0 to 9 is represented by a short series of black and white stripes of different widths. The barcode digits can be deciphered as follows:

- First section: country where it was issued.

- Second section: manufacturer of the product.

- Third section: the product itself.

Different types of the same basic product have totally different barcode numbers.

How to Make Barcodes

To create barcode, you can use special software, such as a barcode generator or barcode label maker. It is also possible to find barcode generator online.

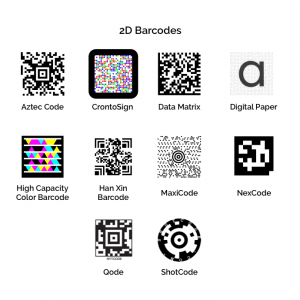

A standard UPC typically looks like a line of vertical stripes with a series of numbers printed under it, but there are also other types of barcodes – 2D barcodes, or QR codes, which look like black-and-white squares with random square-shaped dots that can be read with a QR scanner.

QR codes were first developed by the auto industry in Japan, but the QR code system reached prominence outside of this industry quickly because of its capacity to read codes fast and store more data than previous code systems.

Most people use QR codes regularly, and retail chains have adapted use of QR scanners due to them being easy to use, versatile, and adaptable to modern technology.

You see QR codes commonly on smartphones and web-based purchases the require an in-person scanner, like package delivery and tickets for concerts, movies, and other events. QR scanners and codes have also been adopted in the marketing world, as an easy way for smartphones to download coupons or mobile applications.

What Is a Barcode Scanner and How Scanners Work?

You need a barcode scanning set that consists of a barcode scanner and barcode scanning software. A barcode scanner quickly reads information from a barcode label and then sends it to a computer where the barcode scanner software is installed, to identify the product that is being scanned.

So, how do you read a barcode? Basically, this is how it works:

- Either LED or laser light points onto a barcode.

- The light reflects back off barcode into a photoelectric cell, a component that detects light.

- The cell generates a pattern of on-off pulses that correspond to the black and white stripes.

- An electronic circuit that is attached to the scanner converts these pulses into digits.

- The digits are then sent to a computer that is attached to the barcoding scanner.

- The barcode scanner deciphers the code.

Types of Barcode Scanners

There is a wide variety of barcode readers to choose from.

They can be standalone, when you need to move the product over the scanner, or pen-type, where you move the scanner over the product’s barcode. They can also be laser-based (typically in big retail stores) or LED-based, wired or wireless. Finally, there can be a two-in-one QR code and barcode scanner.

The choice of a barcoding scanner depends on the industry where it is going to be used. The simplest and most affordable type of a barcode scanner is a USB scanner.

One of the most known barcode reader brands is Honeywell. You can visit the Honeywell online shops to choose a scanner that best fits your business.

What Industries Use and Benefit from Barcoding?

Of course retail is the biggest industry that uses barcodes. Scanning barcodes at checkout speeds up the service and reduces time that needs to be spent in line.

Another industry where barcode scanning is widely used is healthcare. Barcode scanners are used in hospitals not only to track inventory such as medications or surgical equipment but also record the patient data.

A barcoding scanner can also be used in educational and governmental institutions to track various fixed assets, such as computers or military equipment.

There have also been developments that brought barcode scanning into the technology and marketing spaces, especially with QR codes.

The bottom line is that any industry where inventory needs to be tracked, barcodes and barcode software are widely used.

Dynamic Inventory Barcode Scanner Software

Dynamic Inventory software supports all types of barcodes and offers convenient tools to create a barcode. You do not need any advanced knowledge on how to make a barcode, because the user interface of Dynamic Inventory barcode printing software is intuitive and user-friendly.

Of course, you can generate barcodes online, but for further work you need more sophisticated software, and that is where the Dynamic Inventory can help. In addition to barcoding scanner software, Dynamic Inventory offers a wide range of inventory management and order processing instruments.

Check out Dynamic Inventory barcode scanner software to see what it can offer.

Learn how Dynamic Inventory can streamline your business today!

Schedule a DemoRelated Articles

see all

Step-By-Step Guide To Creating Your Own Barcodes

Creating powerful networks that help your company run smoothly is essential to building a successful retail business. A lot of …

The 15 Essential Facts About 2D Barcodes

If you take a closer look at any modern barcode, you may notice that it contains not only stripes, but …

How To Use QR Codes Effectively

It is hard to imagine today’s everyday life without QR codes. They have become so integrated into our routines that …